Top Tips: Examining Brand Protection Features with VSC

Both high-end and everyday items can be subject to counterfeiting, making brand protection a vital consideration across many industries. The most visible elements of genuine items are often accurately recreated by counterfeiters, making it difficult to detect fakes at a glance. However, subtle or embedded security features are often overlooked in the manufacture of counterfeit goods, and can be examined to determine whether an item is genuine. Today, many brands employ specific brand protection features to deter counterfeiters and safeguard their identity and reputation.

Brand protection features are applied to a wide variety of items, such as alcohol, cigarettes, vape cartridges, pharmaceuticals, and electronic devices. Some methods that are utilised include holograms, colour-changing or UV-fluorescent inks, and micro-printed lines or watermarks.

Read on as we share our three top tips for examining brand protection features using our VSC workstations:

1: OVD Lighting

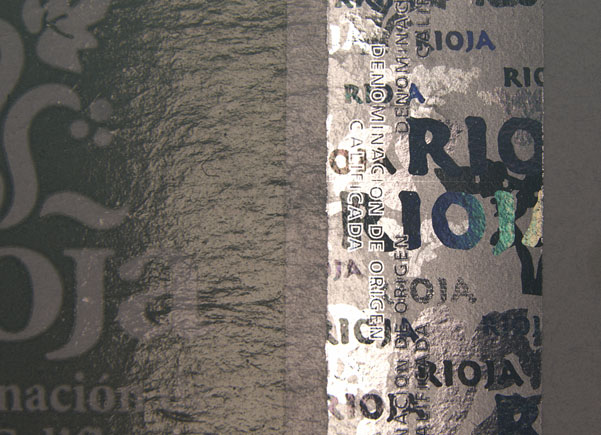

When examining an item for the detection of brand protection features, there are many light sources that are helpful. Optical Variable Device (OVD) lighting uses white lights from different angles, usually used to view diffractive security features such as holograms or kinegrams.

Cycling through the lights in the OVD array allows for the full examination of any of these security features. The visual angle, lighting conditions and resulting optical effect can be compared frame by frame between a genuine and a suspect item to aid in the determination of the item’s authenticity.

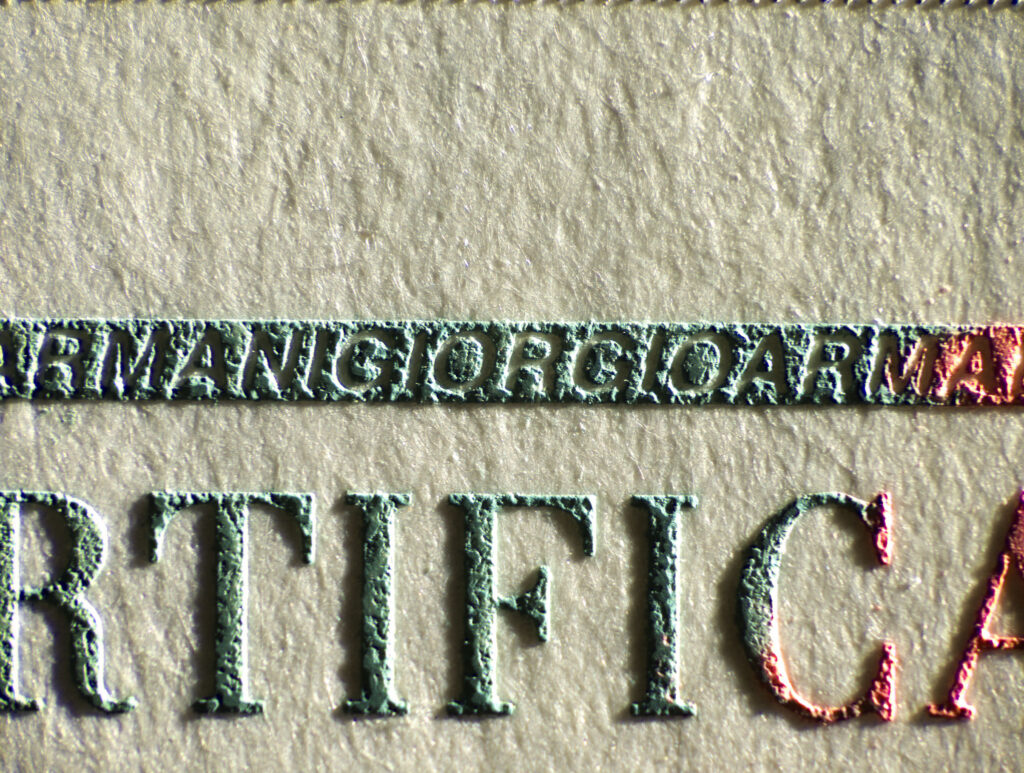

Image: Example of a diffractive security feature on a wine label

2: Compare

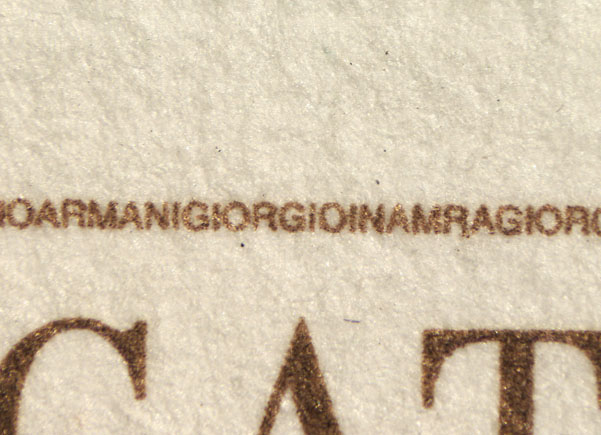

Microprinting involves printing extremely small text or fine line patterns that appear as a solid line or border to the naked eye. Most home or office printers are not able to achieve the resolution needed to be able to replicate the microtext cleanly. When magnified, authentic microtext appears crisp and evenly spaced, but counterfeit microtext will often appear blurred, broken, or as a solid line.

Examine a genuine item and take reference images of any available microtext at a high magnification and under varying light sources. Use the compare function to open a reference image of genuine microtext for comparison with the questioned microtext to best visualise discrepancies in printing quality.

Image: Example of microprinting on clothes tag

3: Remove the Base

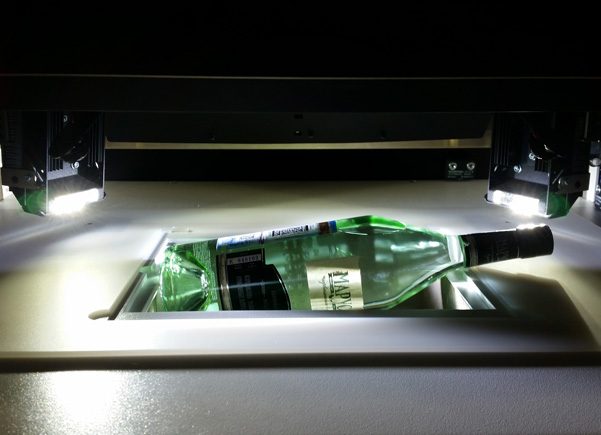

If the suspected item is three-dimensional, like a wine bottle, then removing the document platen and transmitted light sources will create more room for the item. This provides a larger field-of-view and creates a larger internal volume.

The bases of the VSC90 and VSC900 can be removed to create extra room for such three-dimensional items. The VSC9000 has a larger internal capacity and A4 field-of-view for the visualisation of larger items, as well as the Translight Tray accessory which allows for a greater working distance.

Image: A bottle inside the VSC9000, using the Translight Tray accessory.

WEBINAR: Forensic Technology for Brand Protection

Join us for this free, on-demand webinar as we explore how we can use cutting-edge technology to investigate and reveal hidden security features in packaging that help protect your brand and products.

Learn more about the VSC range

Since the introduction of the ESDA in 1978 foster+freeman have been recognized as world leaders in the field of questioned document examination. Today, foster+freeman VSC systems can be found in airports, border crossings, immigration controls, banks and forensic laboratories worldwide.